The Research Engineers brand is synonymous with PAPI. Manufacturing the very first PAPI in the 1960’s, RE has remained a market leader ever since. Building upon the sound engineering principals and risk-averse methodology necessary for such a safety-critical piece of airfield lighting infrastructure, Research Engineers has developed the RE LED PAPI.

Contact Airport Lighting Specialists today to find out why the Research Engineers LED PAPI is the product of choice for the Royal Air Force, the Royal Australian Air Force and numerous major airports worldwide.

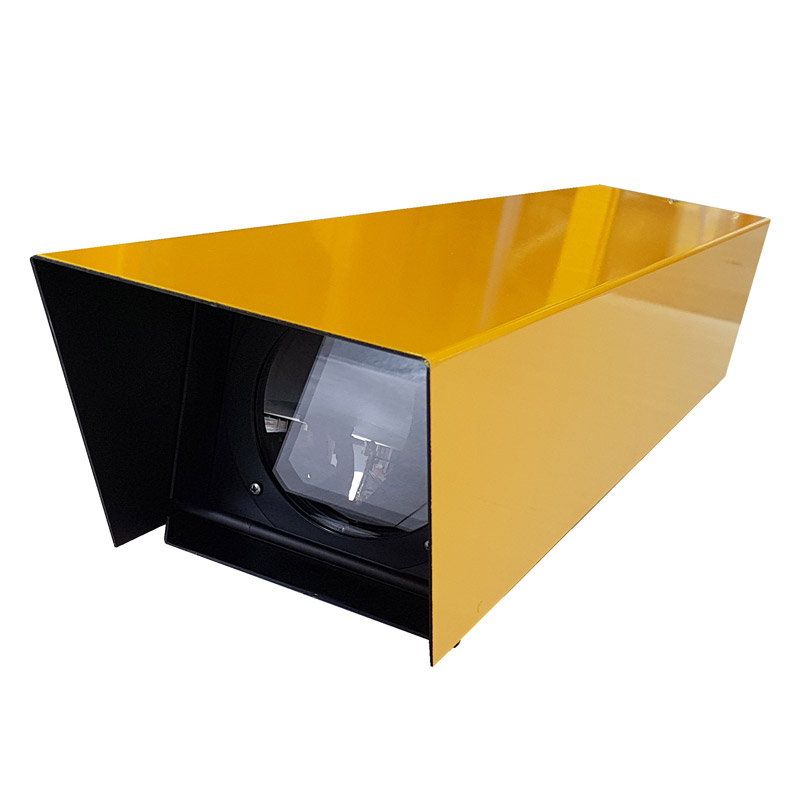

LED PAPI

For 6.6A Series Circuits

The new LED PAPI retains the features that made the original PAPI the most highly regarded and widely used product on the market. The compact dimensions and field replaceable projectors make maintenance easy and convenient. LED PAPI uses 75% less power than a lamped equivalent and can be powered by Series Circuit, Mains AC or 24 volt DC.

The modular concept

Interchangeable Projectors – Simplifying maintenance & spares management.

Minimal Field Maintenance – Individual projectors can be replaced in seconds.

Stable Reference – Projectors are mounted on a precision base plate.

Features

- Same modular design and mounting as original RE PAPI.

- Power consumption reduced by 75%.

- Sharper transition.

- Multi power and control methods.

- Sealed projectors.

- Front lens blast protection.

- High efficiency, low power LED light engine.

- Individually field-replaceable projectors.

- Simple cable connection.

- Includes lens heater to prevent frosting.

- LED intensity follows halogen dimming curve.

- Dust ingress protection to IP54.

- Field replaceable front glass.

- Suitable for operation with 50W to 200W series isolation transformers.

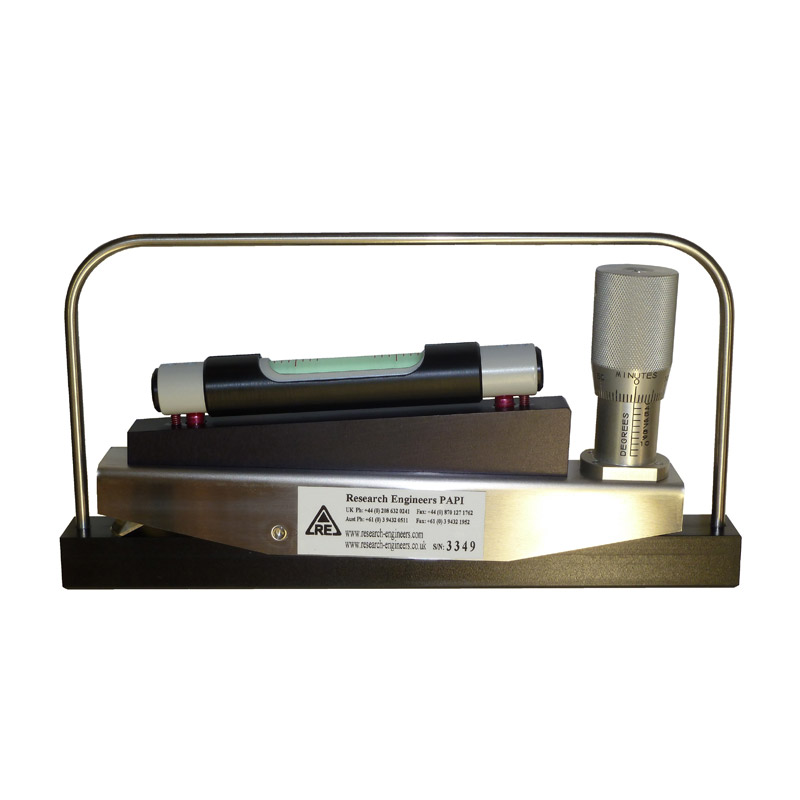

Clinometer

- Precision spirit level with micrometer screw adjustment

- Calibrated in degrees and minutes

- Overall accuracy better than 1 minute of arc

- Operating range from -50 C to +70 C

- Supplied in protective fitted case

Precision Base Plate

- Available in 2-projector or 3-projector format

- Rigid and stable in all environmental conditions

- 3-leg mounting eliminates induced stresses

- Provides repeatable clinometer location

- Anodised aluminium alloy construction

Compliances

- CASA Part 139 (Aerodromes) Manual of Standards – Ch 9 (PAPI)

- ICAO Annex 14 Vol 1 – Ch 5.3.5 (PAPI and APAPI)

- UK MoD RA 3515(8) & RA 3515(29)

- FAA Engineering Brief No. 67D